Personalized Digitizing for Embroidery: Customized to Your Demands

Personalized Digitizing for Embroidery: Customized to Your Demands

Blog Article

Grasping the Embroidery Digitizing Refine: Your Ultimate Guide

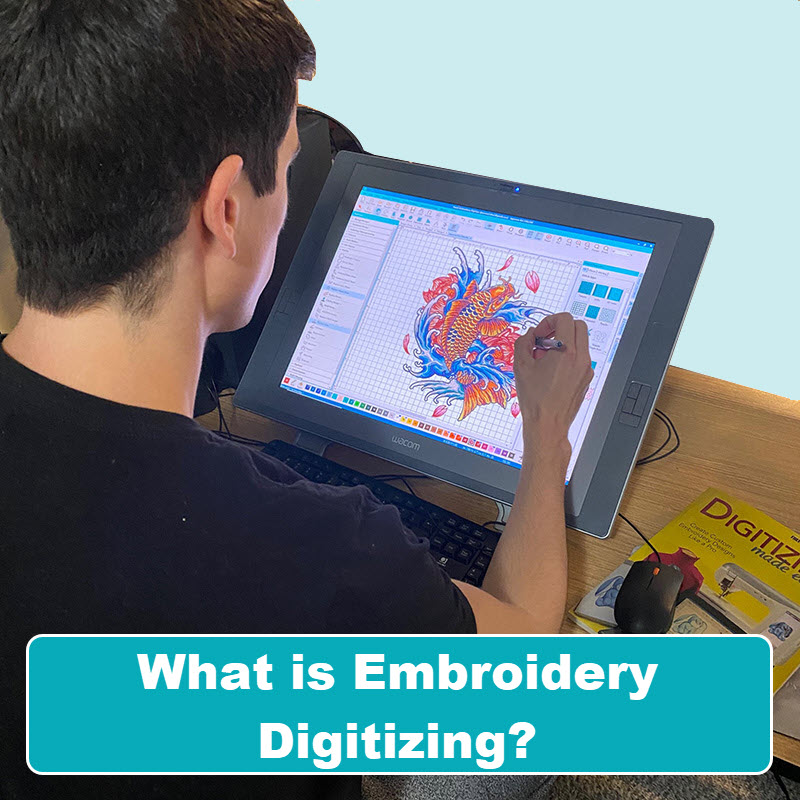

Embroidery digitizing is a thorough craft that needs accuracy and competence to equate detailed styles right into electronic styles for machine embroidery. As artisans get started on this journey to understand the needlework digitizing process, a detailed understanding of the basics establishes the structure for quality. Beyond the simple knowledge lies a realm of advanced software application, specialized devices, and nuanced techniques waiting to be checked out. By diving into the nuances of digitizing, one can unlock a world of innovative opportunities and boost their embroidery projects to brand-new elevations.

Understanding Needlework Digitizing Essentials

Needlework digitizing essentials form the structure whereupon intricate designs are translated into machine-readable formats for precise stitching. This initial step in the needlework digitizing procedure is crucial for guaranteeing that the final embroidered item is a faithful depiction of the original layout. Understanding embroidery digitizing basics involves grasping key concepts such as stitch kinds, sew instructions, density, underlay, and pull compensation.

Sew kinds play an important function in figuring out the visual and textural outcome of the embroidered layout. By picking the proper stitch type, whether it be satin, fill, or running stitch, digitizers can accomplish the desired effect and boost the total high quality of the needlework. In addition, sew instructions affects the flow and dimension of the layout, while density figures out the spacing and protection of the stitches.

Furthermore, padding stitching supplies security to the style by securing the textile and stopping distortion during the needlework process. Draw payment is an additional crucial consideration to counteract the all-natural propensity of material to agreement when stitched. Understanding these embroidery digitizing essentials is essential for creating professional-quality stitched products.

Picking the Right Digitizing Software

Picking the appropriate digitizing software application is an essential decision that dramatically impacts the effectiveness and top quality of the embroidery digitizing process. Digitizing for Embroidery. When selecting the right digitizing software application, it is essential to think about variables such as the complexity of styles you intend to develop, the user-friendliness of the software, the level of client assistance used, and the compatibility with your needlework machine

There are various digitizing software application alternatives available out there, varying from standard programs for beginners to advanced software for professional digitizers. Some popular choices include Wilcom EmbroideryStudio, Hatch Needlework Software, and PulseID. These software packages offer a vast array of tools and functions to assist you produce detailed styles effortlessly.

Prior to choosing, it is advisable to discover the different software alternatives through totally free trials or demos to establish which one ideal fits your requirements. Additionally, reviewing testimonials and seeking recommendations from experienced digitizers can give beneficial insights right into the staminas and weaknesses of each software plan (Digitizing for Embroidery). By carefully reviewing your demands and contrasting the attributes of various digitizing software, you can make an educated choice that improves your embroidery digitizing process

Digitizing Tools and Methods

Optimizing Layout Setup for Needlework

Understanding the details of layout setups is basic in attaining ideal cause the needlework digitizing process, building upon the foundation laid by understanding digitizing devices and methods. When enhancing style settings for embroidery, it is important to consider factors such as stitch kind, thickness, rug, pull compensation, and registration. Sew kind choice impacts the general feel and look of the design, with options like satin, fill, and running stitches offering various structures and effects. Density describes the spacing and density of stitches, affecting the design's insurance coverage and longevity. Correct rug stitching gives security and prevents textile distortion, particularly for intricate designs or on stretchy products. Pull compensation readjusts for material stretch throughout stitching, redirected here guaranteeing accurate style replication. Enrollment settings straighten different components of the style accurately, preserving overall layout integrity. By fine-tuning these layout webpage settings, embroiderers can boost the quality and accuracy of their embroidered productions.

Troubleshooting Common Digitizing Issues

When coming across common digitizing problems throughout the embroidery procedure, it is vital to recognize the source and implement efficient solutions immediately. One usual problem is stitch thickness issues, where stitches might be too thick, causing the material to pucker, or too thin, bring about voids in the style. Changing the stitch density settings in the digitizing software can aid settle this problem.

One more regular challenge is thread breaks during the needlework procedure. This can take place because of various factors such as wrong tension settings, boring needles, or utilizing low-quality string. Making sure appropriate upkeep of the embroidery machine, including normal needle changes and tension adjustments, can reduce the occurrence of thread breaks.

Moreover, style registration mistakes can lead to misaligned elements within the needlework design. Inspecting the style positioning in the digitizing software application and making necessary changes prior to sewing can assist in preventing this problem. By attending to these typical digitizing problems immediately and successfully, you can make certain a smoother embroidery procedure and high-quality ended up items.

Verdict

Finally, grasping the embroidery digitizing procedure calls for a strong understanding of the fundamentals, the ideal option of software, and knowledge of devices and methods. Enhancing layout settings and troubleshooting usual digitizing problems are important action in ensuring high-quality needlework outcomes. By following these actions my sources carefully, one can accomplish accuracy and effectiveness in the digitizing process.

Report this page